Key Takeaways

- Scrap metal recycling is essential for reducing waste, conserving natural resources, and lowering greenhouse gas emissions.

- Innovative technologies are enhancing the efficiency and quality of the recycling process.

- The industry supports economic growth, job creation, and sustainability worldwide.

- Ongoing challenges include policy support, infrastructure needs, and stable scrap supplies.

Table of Contents

- Introduction

- Environmental Benefits of Metal Recycling

- Energy Conservation Through Recycling

- Economic Impact of the Scrap Metal Recycling Industry

- Technological Advancements in Metal Recycling

- Challenges in Scrap Metal Recycling

- Policy and Regulatory Considerations

- Conclusion

Introduction

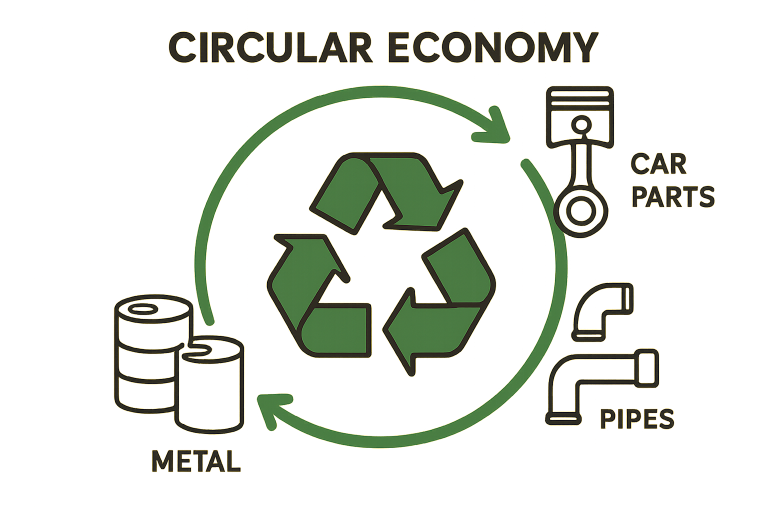

Scrap metal recycling is a pivotal element of the modern circular economy, where the primary aim is to extend the life cycles of materials and minimize waste. By turning discarded metal into reusable resources, scrap recycling reduces environmental strain and fosters a culture of sustainability. Individuals and businesses looking for efficient ways to contribute to this green initiative can turn to services like scrap metal NJ, which makes metal recycling accessible and effective throughout local communities.

Metals such as aluminum, copper, and steel are infinitely recyclable, making them critical players in the shift from a linear “take-make-dispose” model to a circular one. This transformation not only helps preserve finite resources but also mitigates the environmental impact of raw material extraction, thereby minimizing pollution and energy consumption.

Environmental Benefits of Metal Recycling

One of the most significant advantages of metal recycling is its substantial reduction in environmental harm. Mining raw metal ores often leads to deforestation, soil degradation, and biodiversity loss, as well as the release of toxic substances into water and air. By recycling existing metals, these detrimental effects are drastically minimized. According to the U.S. Environmental Protection Agency (EPA), recycling aluminum saves up to 95% of the energy used in primary aluminum production, resulting in dramatic reductions in greenhouse gas emissions.

In addition, recycling scrap metals also reduces landfill waste. As metals can take decades or even centuries to break down, their recovery and reuse prevent environmental contamination and promote healthier ecosystems.

Energy Conservation Through Recycling

The energy savings achieved through scrap metal recycling are remarkable. For example, recycled steel production uses up to 74% less energy than manufacturing from raw iron ore. This not only reduces industrial costs but also lessens the overall carbon footprint of manufacturing industries. These efficiencies help slow climate change and preserve energy resources for future generations.

As industries and governments focus on achieving ambitious sustainability goals, the importance of adopting recycled metals cannot be overstated. Initiatives in various regions demonstrate that embracing scrap recycling can play a significant role in national and corporate strategies to cut carbon emissions and transition towards net-zero targets.

Economic Effect of the Scrap Metal Recycling Industry

The scrap metal recycling industry is a robust economic engine, directly and indirectly supporting hundreds of thousands of workers worldwide. In the United States alone, this dynamic sector generates over $105 billion in annual economic activity and supports approximately 500,000 jobs, spanning collection, sorting, transportation, processing, and resale.

The financial benefits extend beyond job creation. By supplying industry-ready recycled metals, recyclers help manufacturers reduce production costs associated with mining and refining raw materials. Metal recycling also drives local business growth and creates valuable revenue streams for municipalities and entrepreneurs participating in collection and trade.

Technological Advancements in Metal Recycling

Modern advancements are revolutionizing metal recycling, making the process cleaner, faster, and more precise. Technologies such as artificial intelligence (AI) and robotics are now widely used in material recovery facilities to automate metal sorting and enhance the purity of recyclate. Advanced methods like X-ray fluorescence spectroscopy enable accurate identification and separation of metal alloys, resulting in higher-quality secondary metals ready for industrial use.

Continued investment in new technology is enabling the industry to recycle even the most complex metal products, from electronic waste to multi-layered automotive parts. As these technologies become more widespread, the efficiency and viability of scrap metal recycling continue to improve.

Challenges in Scrap Metal Recycling

Despite its benefits, the scrap metal recycling industry faces notable challenges that must be addressed for sustainable growth. Market fluctuations—such as price fluctuations in raw and recycled metals—can affect profitability and limit supply. Additionally, the industry requires ongoing investment in advanced sorting, processing, and logistics infrastructure to keep pace with demand and regulatory standards.

Contamination of metal scrap with non-metallic materials or hazardous substances also impedes efficient processing. Overcoming these barriers is essential for maintaining the sustainability of metal recycling and realizing its full potential within the circular economy.

Policy and Regulatory Considerations

The success of scrap metal recycling is closely tied to policy development, regulatory oversight, and effective incentive structures. Apparent and standardized policies can help streamline recycling practices, benefit the environment, and ensure that economic benefits are widely shared. Governments around the world are implementing or considering extended producer responsibility (EPR) laws, which require manufacturers to manage the end-of-life phase of their products, further incentivizing recycling and the use of recycled materials. Public education and improved collection systems also help foster higher recycling rates and create a sustainable loop for metal materials in the economy.

Conclusion

Scrap metal recycling offers undeniable advantages in resource conservation, energy savings, and economic development. Through continued innovation, supportive policy frameworks, and robust community participation, the industry will remain a central force in advancing a sustainable, circular economy. Embracing recycling is more than an environmental necessity—it’s an economic and societal imperative for a greener, more resilient future.

READ ALSO: Top Factors That Affect Brass Scrap Prices in Your Area