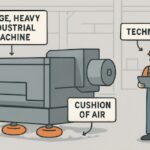

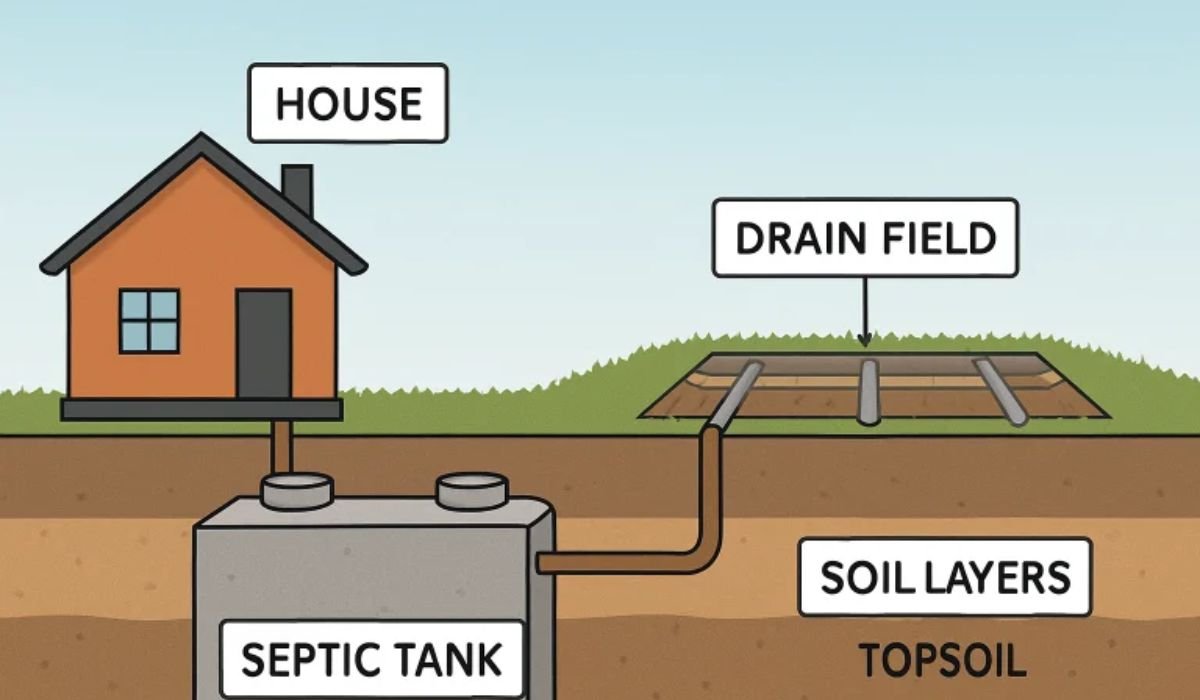

In the race to optimize industrial automation, the need for precise, efficient material-handling solutions has become a defining challenge. Air casters, which harness a thin film of air to float heavy loads, are quickly gaining momentum in this field. By providing almost frictionless movement, these devices ensure that industrial floors are safer, cleaner, and more efficient. Their precision and versatility are opening new pathways to productivity across a range of manufacturing formats. Integral to these improvements is the role of suspension casters, which manufacturers are adopting to reduce downtime and operational risk while increasing the speed and accuracy of load transportation.

Industrial leaders are increasingly adopting air caster technology for its exceptional maneuverability and support for scalable automation, facilitating the reconfiguration of production lines with minimal disruption. This technology improves workflow efficiency and reduces the risk of product damage during the transport of heavy or delicate items, addressing key manufacturer concerns. As air caster technology advances, it is increasingly integrated into modern facilities, aligning with the industry’s shift towards automation and digital transformation.

Air Casters in Modern Manufacturing

Within today’s manufacturing world, air casters are making a significant impression. Their ability to move large, heavy modular components with unmatched precision enables companies to advance flexible manufacturing. In industries such as modular construction, air casters help teams reconfigure assembly layouts on demand, eliminating many of the headaches and risks associated with manual load transport.

For example, manufacturers use air casters to improve the movement and assembly of prefabricated modules, boosting efficiency while minimizing workplace injuries and equipment wear. By allowing heavy loads to glide smoothly on a thin film of air, these systems reduce strain on workers and decrease the likelihood of floor damage. The result is greater productivity, safer working conditions, and a foundation for more advanced automation applications. Such improvements are helping drive record gains in manufacturing productivity across the US and other advanced economies.

Integration with Industry 4.0

The interaction between air casters and Industry 4.0 technologies marks a pivotal shift in manufacturing. As factories digitize their operations, air casters are now integrated with IoT sensors and smart monitoring systems, providing real-time data on load handling, positioning, and maintenance requirements. This digital convergence enhances process transparency and supports predictive maintenance strategies, helping preempt equipment failures and costly downtime.

By coupling air casters with networked systems, operators can automate material movement, improve operator safety, and adapt production flows to meet changing conditions or customer requirements, all with minimal manual intervention. These capabilities position air casters as critical enablers of the smart factory revolution.

READ ALSO: Ensuring Industrial Safety: The Critical Role of Proof Testing

Advancements in Air Caster Technology

Innovation in air caster design has broadened the scope of what can be achieved with this technology. The most recent models have higher weight capacities, include features for safely moving hazardous materials, and incorporate ergonomic refinements for easier use and maintenance. Engineering improvements have also made air casters more robust and adaptable, enabling them to suit a wider array of surface types and operational environments.

These advancements are expanding the reach of air casters into settings where traditional solutions were once required, including highly sensitive cleanrooms, laboratories, and the handling of aerospace components. As manufacturers continue to innovate, air caster adoption is likely to fuel a new wave of operational agility across high-tech sectors.

Applications Across Industries

Air casters are no longer confined to factory floors. In the aerospace sector, they enable precise, damage-free movement of large and fragile components, such as fuselage sections and jet engine turbines. In healthcare and cleanroom environments, air casters move specialized equipment without risking contamination of sensitive spaces. Even in logistics and distribution, air casters are transforming the handling of high-value or oversized goods, adapting to the unique material transport challenges of each sector.

Sustainability and Energy Efficiency

With sustainability now a top priority for manufacturers worldwide, air casters stand out for their lower energy requirements compared to traditional lifting and transport equipment. Because they glide loads effortlessly on a cushion of air, operators need to exert less force, and operations consume less energy over time. Many air caster systems are constructed from recyclable materials, supporting greener manufacturing objectives and reducing industrial waste. Adoption of energy-smart solutions, such as air casters, complements the broader industry shift toward sustainable automation.

Challenges and Considerations

Air caster deployment is not without its challenges. Safe and effective operation requires thorough staff training, and regular maintenance is critical to ensure a long service life. Additionally, integrating air casters into older factory environments may require infrastructure changes or workflow redesigns. While the long-term gains can be substantial, companies need to carefully consider the initial investment and process adjustments required, ensuring a smooth transition that supports ongoing operational goals.

Conclusion

The rise of air casters in industrial automation signals a shift towards more agile, sustainable, and digitally integrated manufacturing processes. Their unique ability to deliver efficient, damage-free, and scalable material handling makes them a driving force in the next era of industrial productivity. With continual advancements in design and connectivity, air casters are set to play an even greater role in shaping the future of smart manufacturing. As industries adapt to the demands of automation, the benefits of air casters will only continue to expand.

YOU MAY ALSO LIKE: Ensuring Industrial Safety: The Critical Role of Proof Testing