Key Takeaways

- Implementing advanced technologies can significantly reduce workplace hazards.

- Ergonomic solutions and automation enhance both safety and operational efficiency.

- Regular training and real-time monitoring are crucial for maintaining a safe work environment.

Introduction

Ensuring workplace safety is both a moral obligation and a smart business practice, directly impacting a company’s productivity, reputation, and bottom line. In today’s fast-evolving industrial environments, proactive strategies that prioritize safety and efficiency allow organizations to reduce hazards while streamlining operations. A foundational element in maintaining safer, more adaptable workspaces includes integrating advancements like leveling casters, which enable smooth movement and stability for heavy equipment, reducing risk and enhancing workflow adaptability.

Beyond physical enhancements, industries are increasingly embracing real-time hazard detection, automation, and data-driven decision-making. These advancements work synergistically with ergonomic equipment and mobile workspace solutions, like those incorporating leveling casters, to ensure both safety and operational ease. The following comprehensive guide outlines the most innovative, actionable strategies for enhancing safety and efficiency across diverse industrial sectors.

Real-Time Hazard Detection

Modern industrial settings rely on sophisticated sensors and AI-powered analytics to detect safety hazards instantaneously. These technologies are capable of monitoring conditions such as gas leaks, live electrical faults, abnormal temperatures, and equipment failures. When hazards are identified in real time, organizations can intervene before escalation, mitigating both injury risks and potential production downtime. Wearable alert devices extend these capabilities to individual workers, providing immediate notifications and fostering an environment of continuous vigilance and responsiveness.

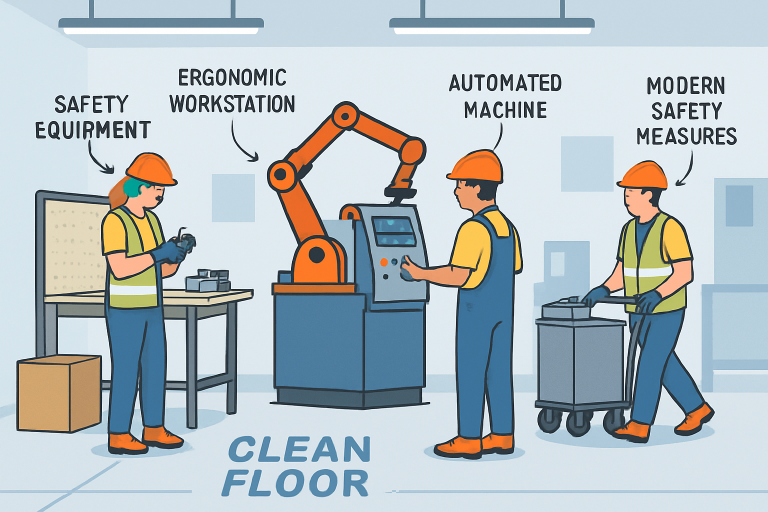

Ergonomic Solutions for Injury Prevention

Many industrial injuries result from repetitive stress and inefficient workstation configurations. To combat this, ergonomic design principles are increasingly being integrated into industrial tools, machinery, and production setups. Adjustable workstations tailored to fit individual workers help prevent musculoskeletal injuries and foster comfort during long shifts. Cutting-edge solutions such as exoskeletons provide physical reinforcement during lifting or overhead work, while smart, user-friendly equipment controls contribute to both safety and productivity. Periodic ergonomic assessments are invaluable in identifying pain points and optimizing task arrangements to protect workers’ health.

Automation and Robotics in Safety

The rise of robotics, automated guided vehicles (AGVs), and smart material handling systems is shaping a new era of industrial safety. These automated systems undertake hazardous tasks—such as handling chemicals, operating in extreme conditions, or transporting heavy loads—thereby removing workers from direct danger. AGVs equipped with advanced navigation tools, including LiDAR and cameras, can safely and efficiently maneuver through facilities, minimizing collision risks and operational bottlenecks. Establishing clear safety protocols and investing in operator education are essential for ensuring smooth human-machine collaboration.

Durable and Protective Industrial Flooring

Industrial flooring solutions are a critical yet often overlooked aspect of workplace safety. Advances in flooring materials have led to surfaces that offer superior traction, resist chemical degradation, and absorb impacts, directly reducing slip, trip, and fall incidents. Facilities investing in robust flooring technologies provide a safer foundation for workers and protect sensitive equipment, especially in areas where heavy machinery or frequent spills are common.

Leveraging IoT for Safety Monitoring

The Internet of Things (IoT) plays a pivotal role in connecting sensors and equipment across industrial worksites. By providing real-time data on environmental conditions and machinery status, IoT networks enable teams to respond instantly to emerging risks, preventing incidents before they occur. Smart systems can monitor air quality, detect gas leaks, and track the well-being of lone workers, ensuring that no threat goes unnoticed. Leading providers like Honeywell, GE Digital, Cisco, and Siemens are at the forefront of IoT-enabled safety platforms, setting industry-wide benchmarks for proactive risk management.

Virtual Reality for Safety Training

Virtual reality (VR) and augmented reality (AR) are next-generation training tools offering experiential learning without exposure to actual hazards. These immersive simulations replicate emergency scenarios, allowing workers to practice correct responses to fires, chemical leaks, equipment malfunctions, and medical emergencies. This hands-on approach boosts knowledge retention and confidence, making employees better prepared for real-life threats. Companies like Caterpillar are pioneering VR-based solutions that transform industrial training practices.

Wearable Technology for Worker Safety

Wearables such as smart helmets, biometric wristbands, and GPS trackers are revolutionizing personal safety monitoring. By collecting live data on workers’ health and environmental conditions, these devices not only deliver immediate warnings to employees but also contribute to organizational strategies for injury prevention. Notable applications include Fujitsu’s heat stress-sensing wristwear, General Electric’s sensor-enhanced helmets for its aviation teams, and PepsiCo’s smart vests that analyze posture and movement patterns to minimize strain-related risks.

Data Analytics for Predictive Safety

Advanced data analytics—often combined with IoT—help organizations identify patterns and predict accidents before they occur. Machine learning models process data from sensors and systems to detect anomalies, perform predictive maintenance, and trigger timely interventions. For example, the Matagami Zinc mine in Canada uses IoT to monitor air toxicity. At the same time, Fastenal implements real-time machine health monitoring, and General Electric leverages predictive analytics to reduce unplanned downtimes. These initiatives underscore how data-driven insights significantly elevate workplace safety.