Industrial facilities are inherently hazardous environments, where even small failures in safety systems can result in major accidents. For safety managers, operators, and plant owners, establishing robust safety protocols is crucial for protecting lives, assets, and business operations. One such protocol, proof testing Houston, TX, is essential for verifying that critical safety systems within industrial plants are capable of performing their intended function when needed the most.

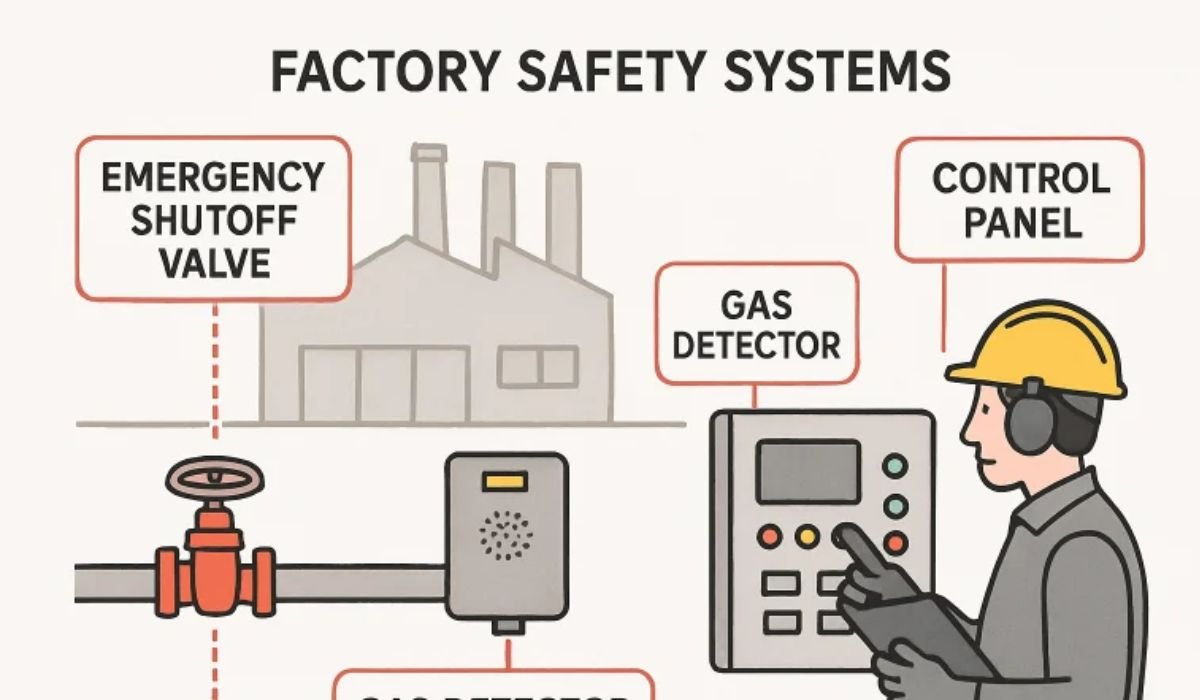

Proof testing involves periodically evaluating safety instrumented systems (SIS), emergency shut-off valves, and detector systems under controlled conditions. This process uncovers hidden failures and ensures that when a real emergency occurs, safety measures respond precisely as required. Industries ranging from oil and gas to chemicals rely on proof testing to stay compliant, minimize downtime, and, most importantly, avert catastrophic incidents.

The significance of proof testing has only grown as industrial processes become more complex and tightly regulated. Today’s best-in-class testing combines traditional methods with technological innovations, striking a balance between operational efficiency and uncompromised safety. As a result, companies adopting comprehensive proof testing strategies safeguard both their workforce and their long-term reputations.

Understanding Proof Testing

Proof testing is a proactive maintenance strategy designed to confirm the continued functionality and reliability of industrial safety systems. By deliberately simulating failure conditions or applying specific stressors, maintenance teams can identify hidden or dormant faults within equipment, reducing the risk of failures during high-stakes situations. The scope often includes testing pressure relief valves, gas detectors, alarm systems, and shutdown interlocks.

A successful proof test helps identify and correct issues before they can cause downtime or safety incidents. More importantly, rigorous testing is often a regulatory requirement, especially in industries where failure to contain hazardous substances could lead to environmental harm or mass casualties.

Importance of Regular Proof Testing

Without scheduled proof testing, critical system failures could go undetected until disaster strikes. Regulatory standards, such as IEC 61511 and OSHA’s Process Safety Management (PSM) regulations, require regular and comprehensive proof testing, with frequencies determined by factors including process risk, manufacturer guidance, and historical performance data. Routine checks may occur monthly for basic functions, while detailed tests are mandated every one to five years, depending on the criticality of the equipment.

Routine and disciplined proof testing not only ensures compliance but also extends equipment lifespan, improves reliability, and provides peace of mind for all stakeholders. Recent reports from the National Institute for Occupational Safety and Health (NIOSH) emphasize that consistent proof testing is one of the most effective ways to prevent rare but catastrophic industrial incidents.

Methods of Proof Testing

- Full Proof Tests: These comprehensive tests simulate emergencies or complete system failure, validating every function of the safety system. They are typically performed during plant shutdowns, providing an opportunity to identify and address complex or compounded faults.

- Partial Proof Tests: Focused on specific components or subsystems, these tests require less downtime and provide a faster way to verify the health of high-risk elements without halting overall operations.

- Remote Proof Testing: Leveraging technology, these tests enable the examination and certification of systems from off-site locations, reducing the need for personnel to enter potentially hazardous environments and thereby accelerating the testing process.

Technological Advancements in Proof Testing

Digital transformation is reshaping industrial safety strategies. Tools such as radar level gauges, wireless sensors, and IoT-based monitoring platforms now enable the automation of proof testing aspects, improving accuracy and safety while reducing labor costs and exposure risks. For example, remote level detection eliminates the need for technicians to climb storage tanks, an operation previously fraught with fall hazards and chemical exposure.

Software-driven analytics can also process proof test results to pinpoint trends, predict future failures, and refine maintenance schedules. This shift towards proactive, data-driven safety management is part of a broader evolution in how industrial plants approach reliability and compliance.

Best Practices for Effective Proof Testing

- Establish a clearly defined and regularly updated test schedule that aligns with standards such as IEC 61508 and considers risk-based factors.

- Invest in modern diagnostic technology and encourage the adoption of partial and remote testing wherever feasible to minimize operational interruptions.

- Maintain meticulous records of all testing activities, including identified faults, corrective actions taken, and the outcomes, to facilitate audits and continuous improvement.

- Conduct routine personnel training aimed at enhancing both technical proficiency and safety awareness.

- Frequently review and update testing protocols, incorporating new technologies and responding promptly to updated regulatory requirements.

Final Thoughts

Proof testing is a cornerstone of industrial safety strategy, ensuring that all systems will function as intended in emergencies. The combination of disciplined scheduling, thorough methodologies, and state-of-the-art technology enables companies to achieve regulatory compliance, protect their employees, and maintain uninterrupted operations. As industrial environments become increasingly safer and more efficient, the role of robust proof testing will continue to grow in importance.

YOU MAY ALSO LIKE: Smart Moves for Safer, More Efficient Industrial Workspaces