Key Takeaways

- Emerging technologies are enhancing the efficiency and sustainability of industrial water purification.

- Innovations such as nanotechnology, advanced membrane filtration, and AI integration are at the forefront of this transformation.

- These advancements address energy consumption, contaminant removal, and system scalability.

Table of Contents

- Introduction

- Nanotechnology in Water Purification

- Advanced Membrane Filtration

- AI and IoT Integration

- Electrocoagulation Techniques

- Biological Treatment Processes

- Decentralized Water Treatment Systems

- Sustainable and Eco-Friendly Methods

Introduction

Industries worldwide are under increasing pressure to optimize water usage and implement sustainable purification technologies. Clean, reliable water is critical for manufacturing, processing, and various operational activities. As global water scarcity intensifies and environmental concerns drive stricter regulations, the demand for cutting-edge solutions has never been greater. Modern advancements such as deionized water services near Baltimore Maryland, revolutionary nanomaterials, and integrated artificial intelligence (AI) systems are reshaping industrial water management. These solutions enhance water purification effectiveness, improve efficiency, reduce operating costs, and enable industries to uphold environmental responsibility.

The evolution of industrial water treatment is influenced by the pace of innovation and the adoption of new technologies tailored to specific needs. From streamlining high-purity process flows to achieving compliance with evolving regulations and corporate sustainability goals, companies worldwide invest in systems that boost productivity while minimizing environmental impact. The focus is now on combining technological performance—such as contaminant removal, resource recovery, and zero-waste operations—with operational realities like scalability, reliability, and cost efficiency. Let’s explore these emerging trends and breakthrough solutions transforming the future of industrial water purification.

Nanotechnology in Water Purification

Nanotechnology is ushering in a new era in water purification, offering precision at the molecular and atomic levels that traditional systems cannot achieve. Nanomaterials such as carbon nanotubes, graphene oxide membranes, and engineered nano-iron particles enable the direct capture, decomposition, or neutralization of hazardous agents—including bacteria, viruses, heavy metals, microplastics, and persistent organic pollutants. By facilitating the targeted removal of complex contaminants previously considered nearly impossible to address, these materials significantly improve water quality and reduce the need for secondary chemical treatments.

The advantages extend beyond superior purification. The unique properties of nanomaterials allow for the development of more compact filtration systems that operate at higher flow rates and reduced energy inputs. This makes them ideal for industries where process water quality is mission-critical, such as pharmaceutical manufacturing, electronics, and precision food production. As industry leaders invest in research and scaling-up efforts, recent market analyses project the water treatment sector will expand at a compound annual growth rate (CAGR) of 9.1%, reaching nearly $3.5 billion by 2030. As these solutions become more affordable and accessible, their influence will continue to grow, setting new standards in purity, efficiency, and resource stewardship.

Advanced Membrane Filtration

Advanced membrane filtration technologies have significantly transformed industrial water purification, achieving unparalleled selectivity and throughput. Methods such as reverse osmosis (RO), ultrafiltration (UF), and nanofiltration (NF) utilize specialized polymeric or composite membranes to separate and concentrate substances ranging from dissolved salts and pathogens to heavy metals and organic compounds. Ongoing advancements in membrane chemistry, including the development of ultra-thin films and the adoption of anti-fouling coatings, have resulted in longer-lasting membranes that require less maintenance and lower replacement frequencies.

Membrane filtration systems are highly customizable, supporting the unique requirements of diverse industries. Even trace minerals or bacteria can compromise product quality or regulatory compliance for sectors such as microelectronics and pharmaceuticals, making these precise filtration solutions indispensable. Energy optimization innovations, such as high-recovery RO units and energy-saving pumps, further reduce operational costs while lowering the carbon footprint of water treatment. Advanced membrane technologies are central to the modern industrial water toolkit thanks to their scalability, automation compatibility, and improved reliability.

AI and IoT Integration

Integrating artificial intelligence (AI) and the Internet of Things (IoT) revolutionizes industrial water treatment operations by introducing unprecedented precision, real-time adaptability, and data-driven optimization. Sophisticated sensors distributed throughout water treatment systems continuously feed data metrics—including pH, turbidity, temperature, microbial counts, and more—into AI-powered analytical platforms. These systems do not merely monitor; they autonomously adjust chemical dosing, alter filtration rates, trigger maintenance routines, and predict system performance based on past patterns, all while minimizing human intervention.

This integration is a game-changer for facilities processing variable water qualities or operating in environments where downtime and inefficiency translate to considerable financial losses. Predictive analytics, facilitated by IoT-enabled devices, means that managers receive alerts about system anomalies or emerging issues long before they lead to breakdowns or regulatory violations. Over time, these smart solutions reduce operational costs, waste volumes, and the environmental impact of industrial activities. The shift from manual, reactionary management to dynamic, predictive water treatment offers a strategic edge to businesses seeking resilience amid fluctuating supply and demand.

Electrocoagulation Techniques

Electrocoagulation has emerged as an invaluable solution for industrial sectors handling notoriously tricky effluents, such as those containing finely dispersed solids, dissolved metals, and stubborn emulsified oils. By applying an electric current to electrodes submerged in the water, contaminants are destabilized and aggregated into larger particles, which can then be separated through sedimentation or flotation. This process not only limits the need for added chemical coagulants (which often lead to secondary pollution and increased disposal costs) but also generates less sludge and requires minimal labor to automate and maintain.

This technique has found a home in industries such as metal plating, oil and gas extraction, and food production, where rapid shifts in effluent quality often challenge traditional treatments. Flexibility is a key benefit: electrocoagulation units are modular and can be scaled or decentralized as industrial needs evolve. As research delivers better, longer-lasting electrode materials and more intelligent system controls, electrocoagulation promises to play a larger role in future water strategies, minimizing costs. In contrast, providing innovative, robust contaminant operational costs, waste volumes, and organisms’ remarkable abilities, biological treatment processes offer natural, scalable solutions to degrade organic pollutants, ammonia, and excess nutrients. Innovations like Moving Bed Biofilm Reactors (MBBRs) and Membrane Bioreactors (MBRs) provide ample surface area for microbial communities, while sophisticated, membrane-based separation ensures consistently high-quality effluent. These reactors are designed for automatic process control, reduced odor production, and compact footprints, making them well-suited for urban or space-constrained industrial sites.

Modern bio-reactors are robust enough to handle high-strength or highly variable wastewater streams, supporting stringent discharge regulation compliance, even in challenging scenarios. Importantly, these biological systems underpin closed-loop and zero liquid discharge (ZLD) initiatives, supporting water reuse and the reduction of industrial freshwater dependency. As the demand for circular water solutions grows, so will the role of biological treatment in pursuing a sustainable, responsible industry.

Decentralized Water Treatment Systems

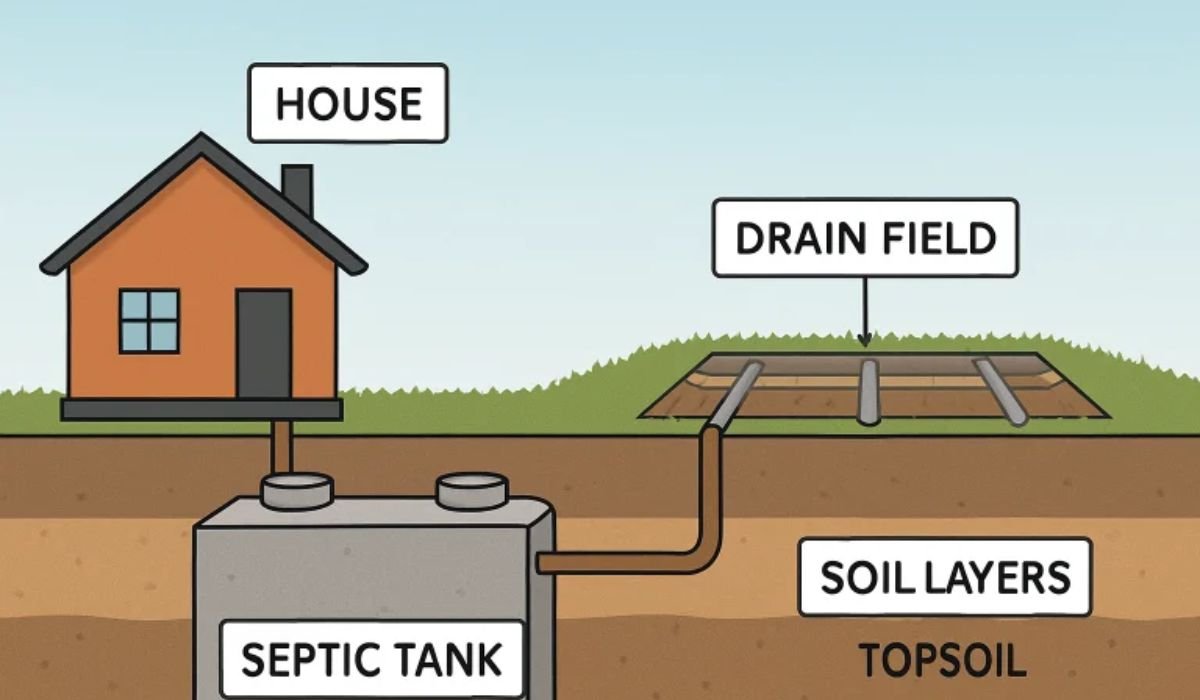

Decentralized water treatment eliminates dependency on centralized systems, transforming operations in remote, rural, or fast-developing locales. These solutions—from skid-mounted and containerized plants to mobile treatment trailers—offer rapid deployment and real-time adaptation to fluctuating demands. Such flexibility is invaluable in disaster response, mining, construction, or wherever infrastructure development cannot keep pace with industrial expansion.

Many decentralized plants are engineered for low-energy operation, often incorporating solar or other renewable energy sources to minimize their environmental footprint. Their modular approach means units can be scaled up, down, or relocated depending on changing operational needs or population shifts. Importantly, decentralized systems deliver immediate, on-site water security and contribute to long-term resilience against climate and supply chain disruptions.

Sustainable and Eco-Friendly Methods

The drive for greater environmental responsibility inspires rapid growth in sustainable industrial water purification practices. Approaches such as biofiltration with natural media, solar-powered desalination, and green-chemistry-based filter media are designed to lower operational costs and environmental impacts. For example, introducing new high-performance RO membranes with extended lifespans and improved energy efficiency means less frequent maintenance, fewer replacements, and dramatically reduced waste.

With strict regulations and growing stakeholder expectations, adopting sustainable water technologies provides more than just environmental benefits. They also offer cost reductions, reputational gains, and future-proofing against carbon or waste taxes. Companies that align their water strategies with eco-friendly, renewable, and energy-smart technologies will be better equipped for long-term growth and compliance, leading toward the next generation of responsible industrial practices.